Laser drilling

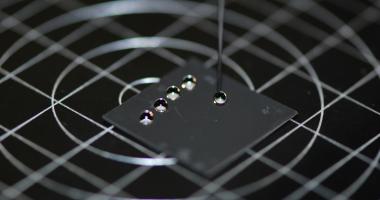

Laser drilling makes it possible to create through or blind holes with variable shape and high aspect ratio, on all types of materials and thicknesses.

The characteristics of laser drilling:

Benefits

- Diameter <10 μm

- Adaptable shape

- Aspect ratio >15

- Drilling transparent materials

- Cylindrical drilling

Performance

- Tolerances of a few μm

- Accuracy of a few μm

- Depth and geometry control

Throughput

- Dependant on material thickness

- From ms to s per hole

Laser workstation

- Pulse duration from fs to ms

- Trepanning head

- Drilling head

- Scanning systems

- Wavelength from IR to UV

Surface condition

Roughness of a few hundreds of nm on the hole inner surface

Process sheet

Areas of application

- Aeronautics

- Automobile

- Electronics

- Diamond spinneret manufacturing

- Watchmaking

- Medical

- Optics

Publications

Associated products or services

-

Selective ablation

The use of a specific pulse duration and/or suitable wavelength(s) makes it possible to work in a condition where the surface layer ablation threshold is lower than the substrate’s. -

Etching - Controlled ablation

Laser engraving is carried out by removing material layer by layer to obtain a 2D or 3D effect on all material types. -

Machining of transparent materials

Cutting, welding, drilling and engraving of transparent materials with minimization of mechanical stress. Short or ultra-short pulse lasers allow transparent materials to be machined with or without removal of material and to modify their intra-volume physical properties. -

Laser cutting

Laser cutting enables precision part production of all material types, even of transparent and hard materials such as SIC and diamond. -

Surface engineering

Laser texturing and surface functionalization make it possible to create effects or generate new properties on all surface types.