Laser processing

Based on the development of customized laser processes for R&D systems, we intervene at every stage of your industrial process.

ALPhANOV's skills, both human and material, allow us to offer a wide range of services in the area of laser processing and to intervene at all stages of the industrial process:

- Studies based on knowledge of laser interaction processes

- Experimental validation thanks to a wide range of laser sources and instruments of control and measurements

- Development an characterisation of industrial processes

- Manufacture of prototypes and small production runs

- Support for the integration of laser machining processes in industrial environment

- User training

Our engineers and technicians have developed and characterised a whole range of laser processes that allow you to drill, cut, mark, engrave, ablate or texture several kinds of materials, on the scale of microns to millimetres with high accuracy, machining quality, conservation of the functionality of materials, and limitation of the heat-affected zone:

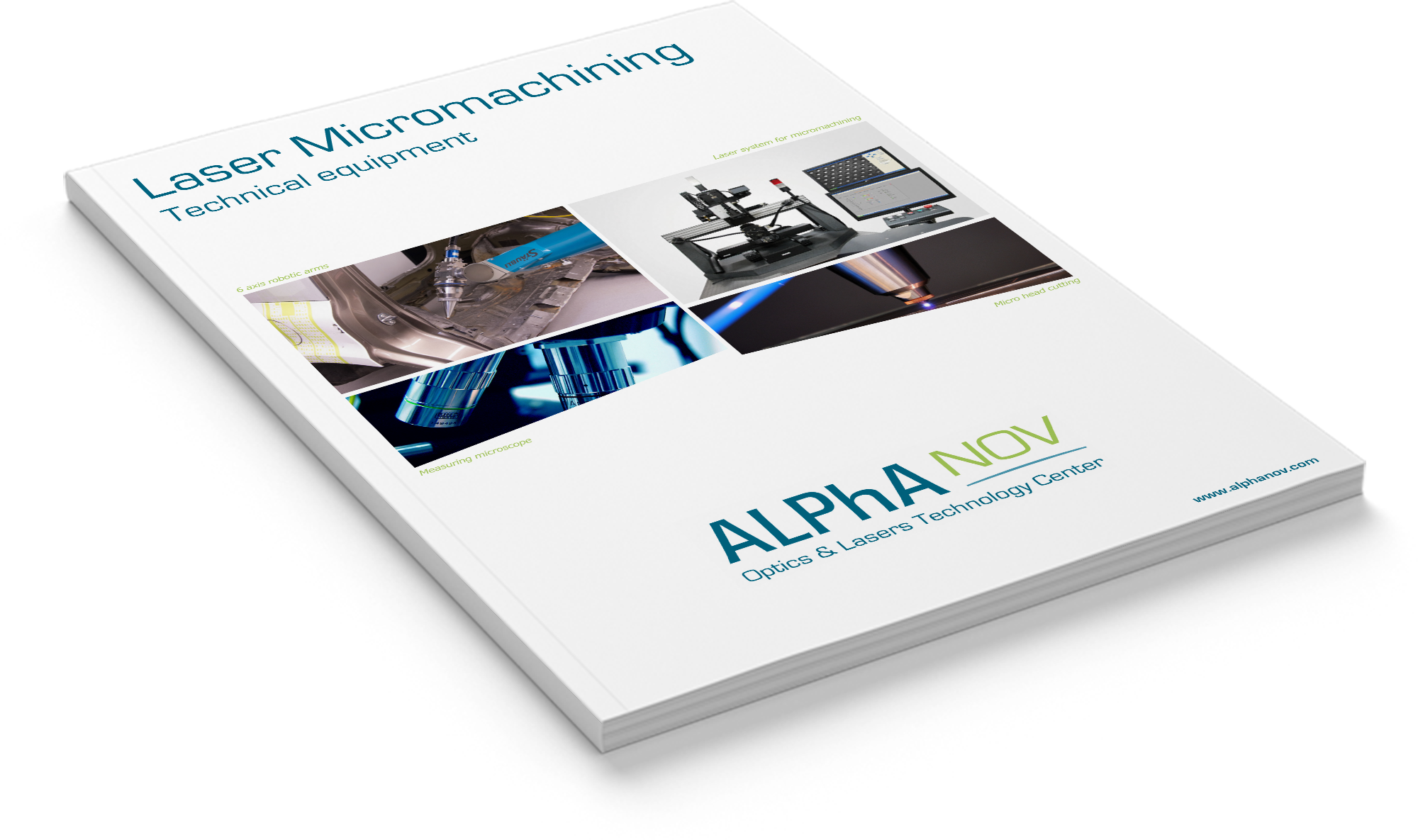

Laser Micromachining

The technical means of laser micro-machining available to ALPhANOV allow it to follow you at each stage of your industrial process. All the technical means are detailed in this document.

Our range of products

-

Selective ablation

The use of a specific pulse duration and/or suitable wavelength(s) makes it possible to work in a condition where the surface layer ablation threshold is lower than the substrate’s. -

Etching - Controlled ablation

Laser engraving is carried out by removing material layer by layer to obtain a 2D or 3D effect on all material types. -

Machining of transparent materials

Cutting, welding, drilling and engraving of transparent materials with minimization of mechanical stress. Short or ultra-short pulse lasers allow transparent materials to be machined with or without removal of material and to modify their intra-volume physical properties. -

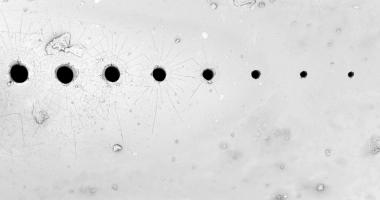

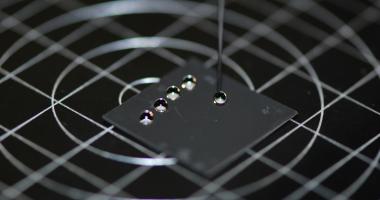

Laser drilling

Laser drilling makes it possible to create through or blind holes with variable shape and high aspect ratio, on all types of materials and thicknesses. -

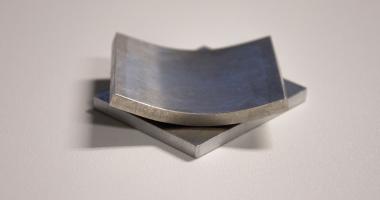

Laser cutting

Laser cutting enables precision part production of all material types, even of transparent and hard materials such as SIC and diamond. -

Surface engineering

Laser texturing and surface functionalization make it possible to create effects or generate new properties on all surface types.

Our related collaborative projects

-

NEXTFAB - MULTIMODAL, FLEXIBLE AND AUTOMATED PILOT LINE FOR HYBRID COMPONENT MANUFACTURING

The NEXTFAB project would provide a multi-technology pilot tool for the 4.0 manufacturing of hybrid components.

Learn more -

SMARTGLASS: photonics-based Sustainable Manufacturing of Abrasion-ResistanT, Anti-Reflective GLASS

To offer an environmentally-friendly laser-based solution for surface-treatment.

Learn more -

KOKICLEAN - Eco-friendly marine coating

Developing and certifying a biomimicry shark skin antifouling treatment based on femtosecond laser texturing for boat paints.

Learn more -

LAUNCH - Additive manufacturing of RF and microwave devices

Developing a suitable wavelength LAser treatment for the coNsolidation-reCtification of 3D microwave patterns.

Learn more -

Newskin - Advanced surface nanotechnologies

Creating an innovation ecosystem to accelerate industrial adoption of advanced surface nanotechnologies.

Learn more -

LASHARE - Industrial laser systems

(2013 - 2019)

To gather and develop knowledge about industrial laser systems and their use throughout the value chain.Learn more -

LASER4FUN - Surface micro-nano structuring

(2015 - 2019)

To develop new surface micro-nano structuring methods using amerging SP/USP laser technologies.Learn more -

AS TGV - Laser percussion drilling

To develop a new femtosecond-laser based technique for high throughput percussion drilling.

Learn more -

ADDIMAFIL - Additive manufacturing by laser fusion

To develop a robotic unit for additive manufacturing by laser fusion of wire for large metallic parts.

Learn more -

PARACETAMOL - Picosecond laser source

To develop a protocol to remove tattoos by laser. In comparison with current tattoo removal techniques, this protocol will allow to remove colored tattoos with a reduction of pain and without side effects.

Learn more -

HELIAM - Metallurgical processing of parts

To develop and commercialize an innovative system allowing the metallurgical processing of parts intended for aeronautics by laser shock.

Learn more -

TresClean - Antibacterial surfaces

To develop of antibacterial surfaces by high power ultra-short laser texturing. The processes developed in the frame of the TresClean project will meet the industrial needs especially in terms of productivity with texturing speeds up to 40 mm/s.

Learn more -

FEMTOWELD - Glass welding and cutting

(2014 - 2017)

Development of a technological solution for glass welding and cutting based on the use of high average power femtosecond laser.Learn more -

UPMOST - Ultrafast laser processing

(2013-2018)

To develop ultrafast laser processing for advanced mobile displays.Learn more -

VESUVE - UV laser for high speed marking

(2012-2016)

To achieve a high rep rate UV laser of industrial reliability.Learn more -

BONEPRINTING - Laser assisted bioimpression

(2011- 2015)

Laser assisted bioimpression for in vivo bone tissue engineering in mice.Learn more -

PERCEVAL - Process of laser scouring

(2011 - 2014)

To develop an innovative process of laser scouring of composite parts.Learn more -

ARCOCE - Rear ceramic composite bodies

(2008-2012)

Research and innovation in the sector composites for aerospaceLearn more

Publications

- Vascularization of Cell-Laden Microfibres by Femtosecond Laser Processing, I. Verit, L. Gemini, J. Preterre, P. Pfirmann, H. Bakis, J-C. Fricain, R. Kling, C. Rigothier - 2022

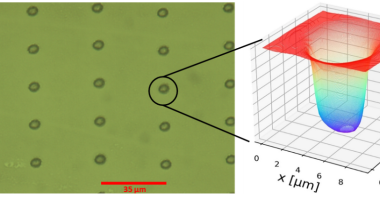

- Pushing laser nano-structuring through mass production, G. Mincuzzi, A. Bourtereau, A. Sikora, M. Faucon, R. Kling

- LIPSS and DLIP: From hierarchical to mutually interacting, homogeneous, structuring, A. Sikora, M. Faucon, L. Gemini, R. Kling, G. Mincuzzi - 2022

- Ablation of Bone Tissue by Femtosecond Laser: A Path to High-Resolution Bone Surgery, L. Gemini, S. Al-Bourgol, G. Machinet, A. Bakkali, M. Faucon, R. Kling

- Intra-volume processing of gelatine hydrogel by femtosecond laser-induced cavitation, I. Vérit, L. Gemini, J.C Fricain, R. Kling, C. Rigothier

- Role of the intensity profile in femtosecond laser surface texturing: An experimental study, A. Sikora, S. Nourry, M. Faucon, B. Chassagne, R. Kling, G. Mincuzzi

- Ablation of Bone Tissue by Femtosecond Laser: A Path to High-Resolution Bone Surgery - L. Gemini, S. Al-Bourgol , G. Machinet , A. Bakkali , M. Faucon, R. Kling