A source generating 60 picosecond pulses for laser fault injection in integrated circuits.

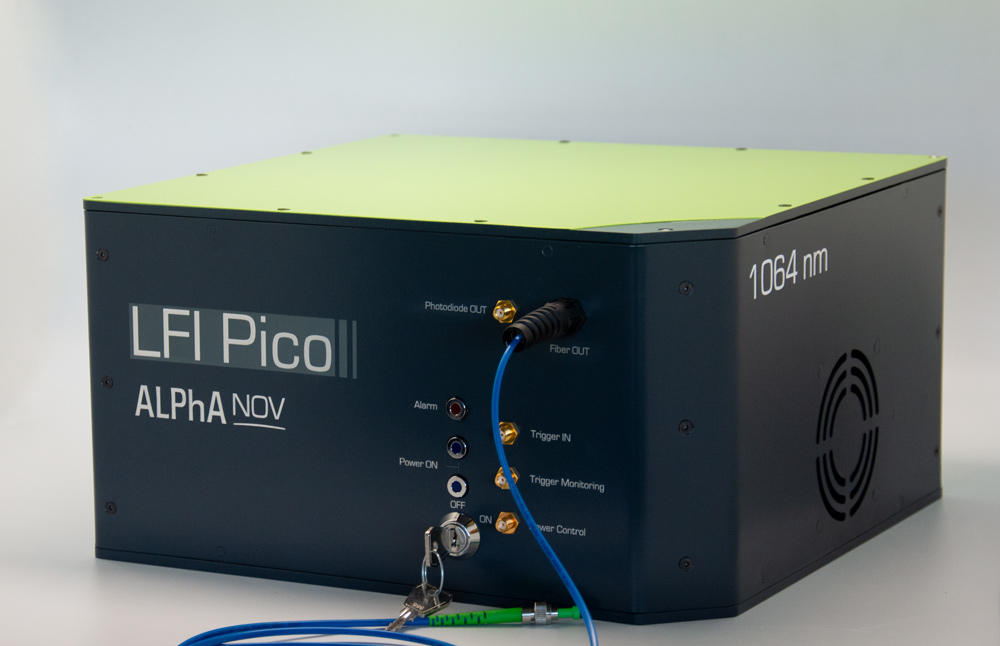

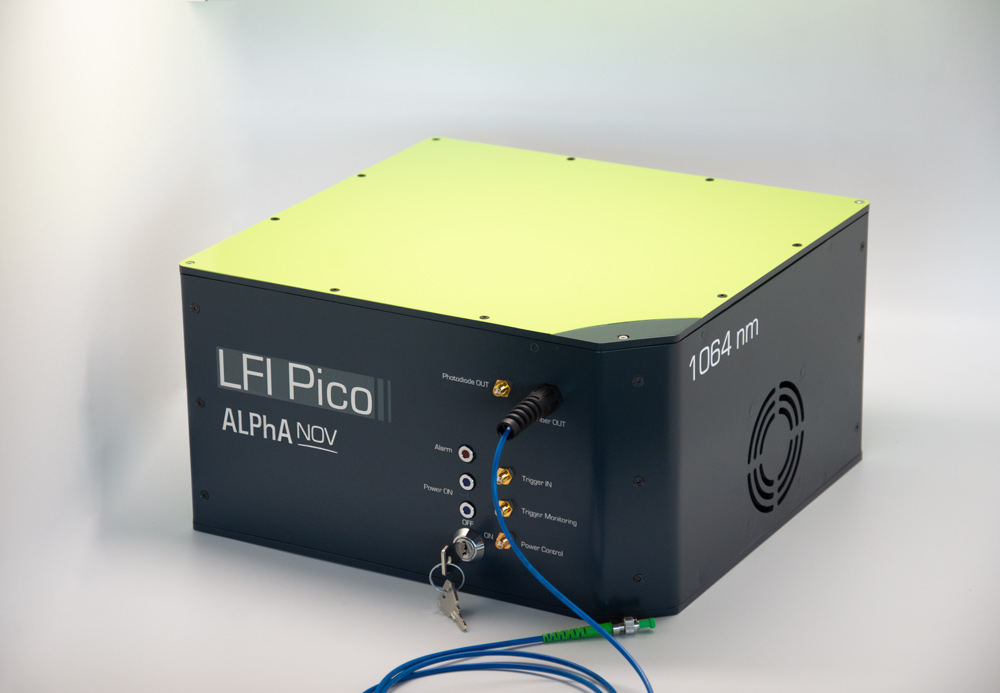

LFI Pico Laser

60 picosecondes pulses

From single-shot to 10 MHz

< 100 ps Jitter

Why use a picosecond laser source to test integrated circuits?

integrated circuits?

The new generations of microcontrollers, SoCs (system on chip) or FPGAs are operating at ever higher frequencies and integrate ever finer technologies.

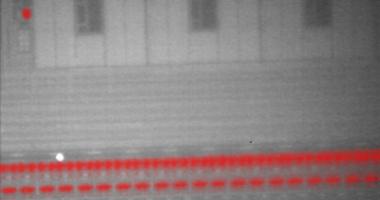

In the security evaluation or failure analysis fields, laser fault injection therefore requires lasers with shorter and shorter pulse durations. Using a source in the picosecond domain opens a new field of exploration. It makes it possible to inject disruptions over short cycle times and to obtain better spatial resolution in order to gather desired effects in the component.

Why is the LFI Pico laser source particularly suitable for this application?

The LFI Pico is an innovative laser source generating 60ps optical pulses, developed specifically for laser fault injection in integrated circuits, whether for security testing or failure analysis.

The particularity of this source compared to the existing one is its ability to generate pulses on demand from a single shot up to 10 MHz, from an external trigger, and most importantly with very low jitter (<100 ps). This feature grants the user extremely precise and predictable timing control of the pulse’s injection into the sample, synchronizing the laser starting from the electronic component under test, and not the other way around. Its fully fibered architecture makes it a particularly reliable and compact laser source.

How is the LFI Pico laser used for fault injection?

A powerful and repeatable laser source is essential in implementing a fault injection attack. Nevertheless, it is the entire optical chain, including the focusing microscope, the component visualization system and also the displacement stages for scanning the sample which must also guarantee excellent attributes. The LFI Pico source is directly compatible with all ALPhANOV laser rigs developed for laser fault injection such as the S-LMS (Single Laser Microscope Station) and the D-LMS (Double Laser Microscope Station) without any modification. For many years these optical rigs have demonstrated their high level of quality, whether through optics transmission, XYZ table repeatability or the performance of the infrared vision system for the back end of integrated circuits.

Product features

- Pulse duration: 60 ps

- Up to 100 nJ per pulse

- All fibered design

- On-demand pulses from single-shot to 10 MHz

- Single mode laser - circular spot down to 1 μm

- Wavelength 1064 nm, adapted for back side fault injection

- Jitter <100 ps

- Python compatible

- Directly compatible with all ALPHANOV microscope systems

Datasheet

Applications

- Integrated circuits evaluation and testing

- Integrated circuits failure analysis

- Laser fault injection

- Single events effects testing

Associated products or services

-

Single laser fault injection microscope - S-LMS

The S-LMS microscope station for laser fault injection is a high-precision platform for security evaluation of integrated circuits. It allows you to focus the laser spot and scan the sample through the back side in order to evaluate the security levels of the electronic components. -

Double laser fault injection microscope - D-LMS

The D-LMS microscope station for double laser fault injection is a platform allowing to focus and scan independently two laser spots for security evaluation of integrated circuits. Ideal for double spot injection processes, it offers all the spatial and temporal flexibility to analyze circuits through the back side. -

Photoemission optical bench

When an integrated circuit is in operation, the zones requested by the routine naturally emit infrared photons via the rear panel. ALPhANOV’s photoemission optical bench allows you to capture and visualise these photonic emissions in order to obtain a precise view of the circuit activity. -

Thermal Laser Stimulation - TLS

The thermal laser stimulation bench is an optical microscope which enables to focus with precision, a PDM+ laser source (Pulse-on-Demand Module) at 1420 nm. Used through the back side of electronic components, the laser beam warms the sample locally and allows to extract and read out data in a memory according to the current consumption of the transistors. -

"Laser fault injection" training

"Laser fault injection" training is dedicated to carrying out laser fault injection campaigns on integrated circuits. She's aimed at cybersecurity and cryptanalysis professionals wishing to develop their expertise in the safety assessment of electronic components.